HaITECNC重型卧式加工中心

Heavy-duty Horizontal Machining Center

”高精度”长寿命”高可靠

1.卧加采用倒“T”结构,为正规的强化型卧式

加工中心结构。立柱为动柱结构前后滑动, HTSK

工作台为左右滑动。本结构具有精度高、刚性强、寿命长的优点,特别适合镗孔与高精度镗孔使用,也适合于端面的强力加工与模具的曲面加工。

2.卧加机体采用独创的三维变径结构设计,经有限元分析,使机体结构得到最大程度的优化,确保机体稳定可靠,能防止机体变形,从而提高机床使用寿命。

3.卧加倒“T”结构的底座,采用蜂窝交错式加强筋,不仅提高的底座的整体重量,增加的底座的刚性与强度,使之重心整体贴近于地面,有效的防止了在机床重型强力切削的时候,切削力对机床所产生的震动。从而保证了机床所加:产品的强力切削与产品精度、光洁度。

4.卧加X、Z导轨一体化整合设计,使X、Z轴的直线导轨全部整合到底座上,来保证机床的稳定性与刚性。

5.卧加立柱采用锥形消边设计,底宽上小的设计增加了机床的稳定性,又避免了长刀杆在加工的时候产生震动,影响精度与光洁度。

6.卧加滚珠丝杠为中空恒温型,配有空调式恒温冷却系统,最大降低丝杆因热变形所造成的精度误差,从而大大提高了机床精度。

7.卧加全封闭式外防护设计,由刀库仓、工件仓与操作仓构成。三仓独立设计互不干扰从而保证操作者与机床的安全。

8.卧加采用我们独创的主动式润滑系统,由数控系统直接控制油泵出油,真正做到了按需注油,并且可以感知机床油路所产生的问题及时为客户产生预警防止机床损坏。

I. The horizontal machining center adopts the inverted "T" structure, which is a regular strengthening type horizontal machining center structure. The column is a moving column structure sliding back and forth, the workbench sliding left and right. This structure has the advantages of high

surface machining

precision, strong rigidity and long life, especially suitable for boring and high-precision boring, but also suitable for end face machining and die

2.The horizontal machining center adopts the original three-dimensiona| reducing structure design, and the finite element analysis makes the structure of the machine optimized to the maximum extent, to ensure the stability and reliability of the machine, and to prevent the deformation of the machine, so as to improve the service life of the machine tool.

3.Horizontal and inverted "T" structure of the base, using honeycomb staggered reinforcement, not only improve the overall weight of the base, increase the rigidity and strength of the base, so that the center of gravity is close to the ground, effectively prevent when the machine tool heavy

and product precision, finish.

force cutting, cutting force generated by the vibration of the machine tool. Thus to ensure the machine tool processing products of strong cutting

the stability and rigidity of the machine tool.

4.Horizontal machining center X and Z guide rail integrated design, so that all X and Z axis linear guide rail integrated on the bottom seat, to ensure

5. The horizontal column adopts conical edge elimination design, and the small design of the bottom width increases the stability of the machine tool, and avoids the vibration of the long tool bar during processing, which affects the accuracy and finish.

6. Horizontal machining center ball screw is hollow constant temperature type, equipped with air conditioning constant temperature cooling system, which can minimize the precision error caused by thermal deformation of the screw, thus greatly improving the accuracy of the machine tool.

7. Recumbent fully enclosed external protection design, composed of tool warehouse, workpiece warehouse and operation warehouse.Three warehouse independent design does not interfere with each other to ensure the safety of operators and machine tools.

8. Horizontal machining center use our original active lubrication system, which directly controls the oil output from the oil pump by the numerical

early warning for customers to prevent machine tool damage.

control system, so as to truly realize the oil filling on demand, and can sense the problems caused by the oil circuit of the machine tool to generate

项目名称 | XYZ坐标行程 XYZ axis travel | 工作台规格(长x宽) Table size | 主轴中心线到工作台距离 | 主轴鼻端到工作台中心距离 |

值 | 800 700 800 | 400*400 | 0-700 | 150-950 |

单位/Unit | mm | mm | mm | mm |

项目名称 | X、Y、Z快速进给速度 X,Y,Z feed speed | 主轴转速范围 Spindle speed | 主轴电机 | X、Y、Z伺服电机 |

值 | 15/15/10 | 50-6000 | 11 | βis30/βis30/βis30/2000 |

单位/Unit | m/min | r/min | KW | KW |

项目名称 | A轴伺服电机 | 数控回转工作台 CNC rotary table | 气源压力 | 盘面高度(水平) Height of the plate |

值 | βis12B/2000 | NRT-400H | 0.6-0.8 | 270 |

单位/Unit | KW | MPa | mm | |

项目名称 | 锁紧油压 | 盘面最大转速 | 最大承重 | 定位精度 |

值 | 35 | 16.6 | 400 | 300/±0.005 |

单位/Unit | kg/cm² | r.p.m | kg | mm |

项目名称 | 重复定位精度 | 工作台T型槽(槽数x槽宽) T slot qty-width*distance | 机床轮廓寸(LxWxH) Overall dimension (L x W x H) | 机床重量(约)Weight(about) |

值 | 300/±0.0075 | 5*14 | 5500*4900*3600 | 14 |

单位/Unit | mm | mm | mm | T |

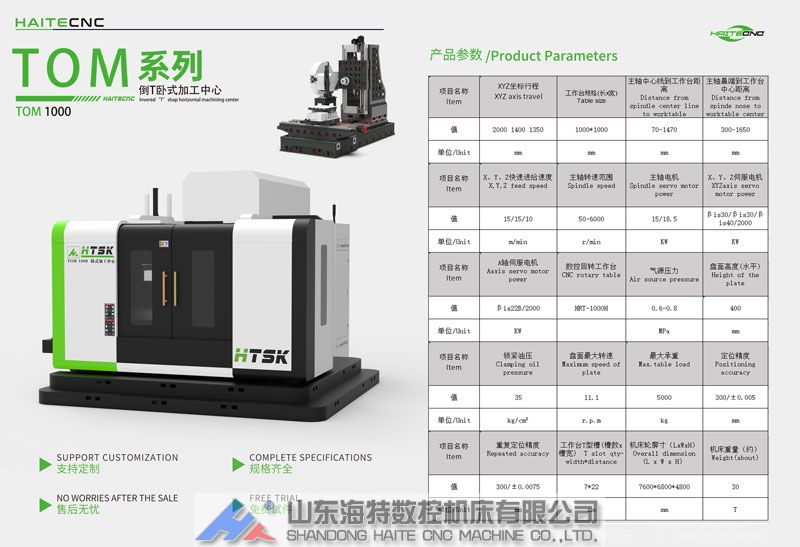

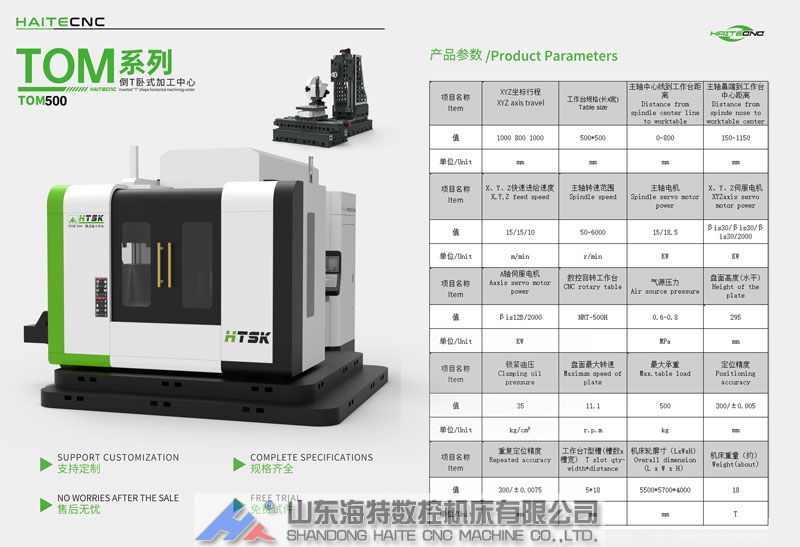

项目名称 | XYZ坐标行程 XYZ axis travel | 工作台规格(长x宽) Table size | 主轴中心线到工作台距离 | 主轴鼻端到工作台中心距离 |

值 | 1000 800 1000 | 500*500 | 0-800 | 150-1150 |

单位/Unit | mm | mm | mm | mm |

项目名称 | X、Y、Z快速进给速度 X,Y,Z feed speed | 主轴转速范围 Spindle speed | 主轴电机 | X、Y、Z伺服电机 |

值 | 15/15/10 | 50-6000 | 15/18.5 | βis30/βis30/βis30/2000 |

单位/Unit | m/min | r/min | KW | KW |

项目名称 | A轴伺服电机 | 数控回转工作台 CNC rotary table | 气源压力 | 盘面高度(水平) Height of the plate |

值 | βis12B/2000 | NRT-500H | 0.6-0.8 | 295 |

单位/Unit | KW | MPa | mm | |

项目名称 | 锁紧油压 | 盘面最大转速 | 最大承重 | 定位精度 |

值 | 35 | 16.6 | 500 | 300/±0.005 |

单位/Unit | kg/cm² | r.p.m | kg | mm |

项目名称 | 重复定位精度 | 工作台T型槽(槽数x槽宽) T slot qty-width*distance | 机床轮廓寸(LxWxH) Overall dimension (L x W x H) | 机床重量(约)Weight(about) |

值 | 300/±0.0075 | 5*18 | 5500*5700*4000 | 18 |

单位/Unit | mm | mm | mm | T |

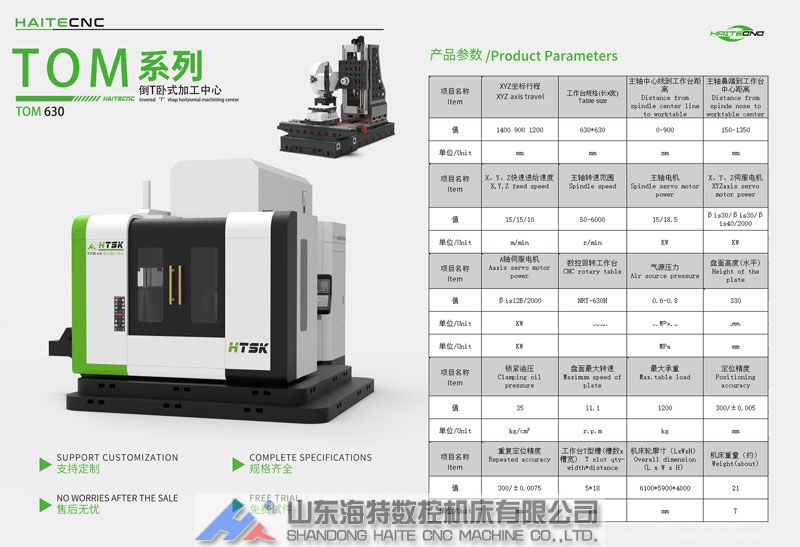

项目名称 | XYZ坐标行程 XYZ axis travel | 工作台规格(长x宽) Table size | 主轴中心线到工作台距离 | 主轴鼻端到工作台中心距离 |

值 | 1400 900 1200 | 630*630 | 0-900 | 150-1350 |

单位/Unit | mm | mm | mm | mm |

项目名称 | X、Y、Z快速进给速度 X,Y,Z feed speed | 主轴转速范围 Spindle speed | 主轴电机 | X、Y、Z伺服电机 |

值 | 15/15/10 | 50-6000 | 15/18.5 | βis30/βis30/βis40/2000 |

单位/Unit | m/min | r/min | KW | KW |

项目名称 | A轴伺服电机 | 数控回转工作台 CNC rotary table | 气源压力 | 盘面高度(水平) Height of the plate |

值 | βis12B/2000 | NRT-630H | 0.6-0.8 | 330 |

单位/Unit | KW | MPa | mm | |

项目名称 | 锁紧油压 | 盘面最大转速 | 最大承重 | 定位精度 |

值 | 35 | 16.6 | 1200 | 300/±0.005 |

单位/Unit | kg/cm² | r.p.m | kg | mm |

项目名称 | 重复定位精度 | 工作台T型槽(槽数x槽宽) T slot qty-width*distance | 机床轮廓寸(LxWxH) Overall dimension (L x W x H) | 机床重量(约)Weight(about) |

值 | 300/±0.0075 | 5*18 | 6100*5900*4000 | 21 |

单位/Unit | mm | mm | mm | T |

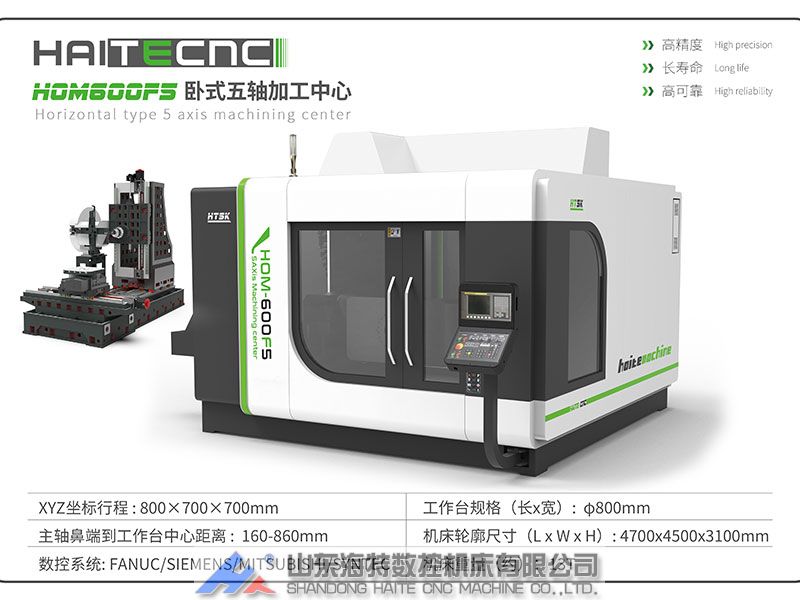

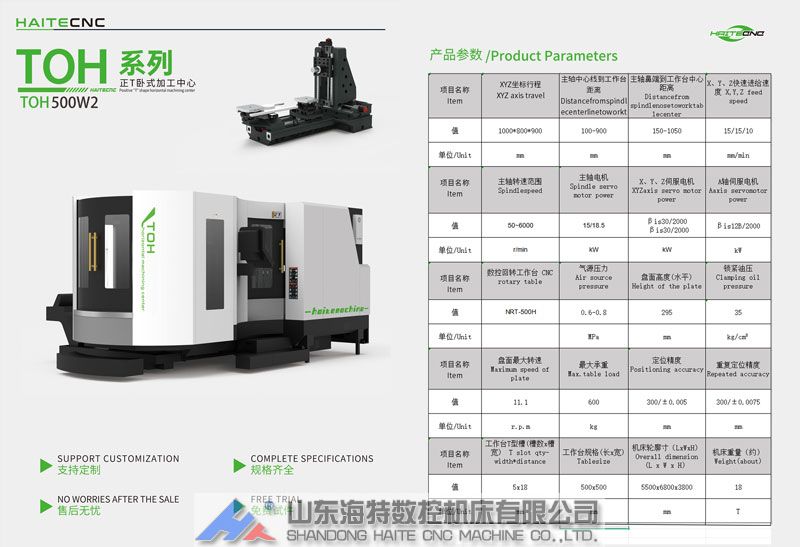

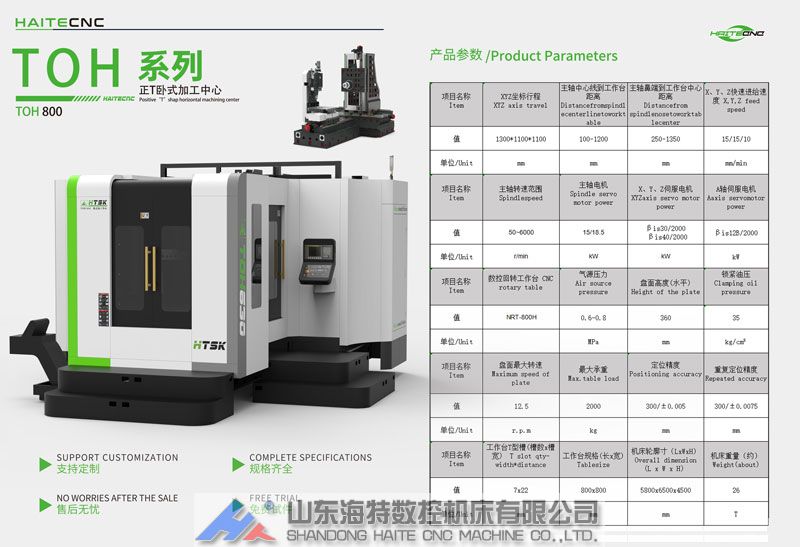

项目名称 | XYZ坐标行程 XYZ axis travel | 主轴中心线到工作台距离 | 主轴鼻端到工作台中心距离 | X、Y、Z快速进给速度 X,Y,Z feed speed |

值 | 1000*800*900 | 100-900 | 150-1050 | 15/15/10 |

单位/Unit | mm | mm | mm | mm/min |

项目名称 | 主轴转速范围 Spindlespeed | 主轴电机 | X、Y、Z伺服电机 | A轴伺服电机 |

值 | 50~6000 | 15/18.5 | βis30/2000 | βis12B/2000 |

单位/Unit | r/min | kW | kW | kW |

项目名称 | 数控回转工作台 CNC rotary table | 气源压力 | 盘面高度(水平) | 锁紧油压 |

值 | NRT-500H | 0.6-0.8 | 295 | 35 |

单位/Unit | MPa | mm | kg/cm² | |

项目名称 | 盘面最大转速 | 最大承重 | 定位精度 Positioning accuracy | 重复定位精度Repeated accuracy |

值 | 16.6 | 500 | 300/±0.005 | 300/±0.0075 |

单位/Unit | r.p.m | kg | mm | mm |

项目名称 | 工作台T型槽(槽数x槽宽) T slot qty-width*distance | 工作台规格(长x宽) Tablesize | 机床轮廓寸(LxWxH) Overall dimension (L x W x H) | 机床重量(约)Weight(about) |

值 | 5x18 | 500x500 | 5500x5800x3800 | 16 |

单位/Unit | mm | mm | mm | T |

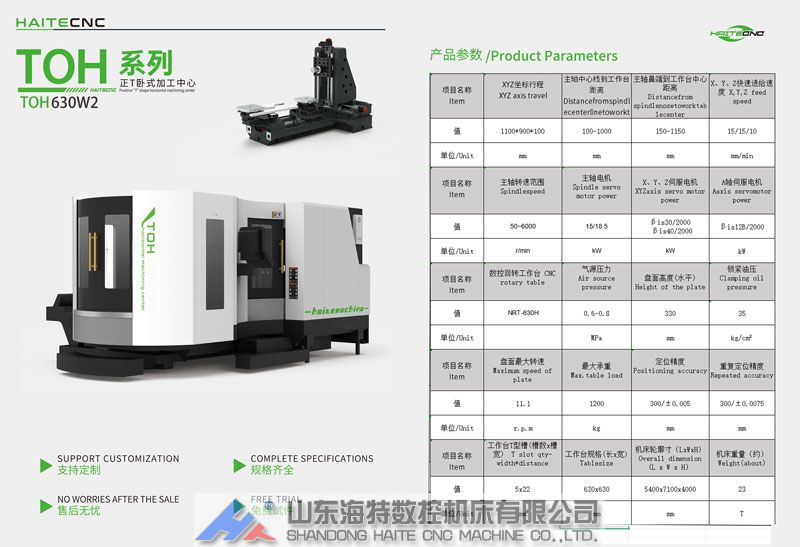

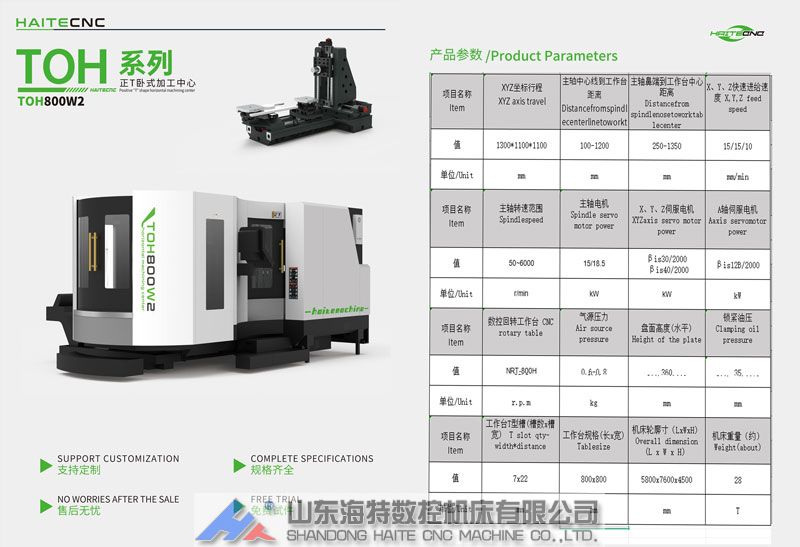

项目名称 | XYZ坐标行程 XYZ axis travel | 主轴中心线到工作台距离 | 主轴鼻端到工作台中心距离 | X、Y、Z快速进给速度 X,Y,Z feed speed |

值 | 1100*900*100 | 100-1000 | 150-1150 | 15/15/10 |

单位/Unit | mm | mm | mm | mm/min |

项目名称 | 主轴转速范围 Spindlespeed | 主轴电机 | X、Y、Z伺服电机 | A轴伺服电机 |

值 | 50~6000 | 15/18.5 | βis30/2000 | βis12B/2000 |

单位/Unit | r/min | kW | kW | kW |

项目名称 | 数控回转工作台 CNC rotary table | 气源压力 | 盘面高度(水平) | 锁紧油压 |

值 | NRT-630H | 0.6-0.8 | 330 | 35 |

单位/Unit | MPa | mm | kg/cm² | |

项目名称 | 盘面最大转速 | 最大承重 | 定位精度 Positioning accuracy | 重复定位精度Repeated accuracy |

值 | 16.6 | 1200 | 300/±0.005 | 300/±0.0075 |

单位/Unit | r.p.m | kg | mm | mm |

项目名称 | 工作台T型槽(槽数x槽宽) T slot qty-width*distance | 工作台规格(长x宽) Tablesize | 机床轮廓寸(LxWxH) Overall dimension (L x W x H) | 机床重量(约)Weight(about) |

值 | 5x22 | 630x630 | 5400x6100x4000 | 21 |

单位/Unit | mm | mm | mm | T |