立式加工中心

Vertical Machining Center

1.机床机体采用独创的三维变径结构设计,经有限元分析,使机体结构得到最大程度的优化,确保机体稳定可靠,又能防止机体变形,从而提高机床使用寿命。

2.机床滑座采用箱体式设计,箱体内部密实的加强筋排列,使机床精度的保持性成倍增加。

3.机床立柱采用我们独创的“驼背”式设计,有效的防止机体变形问题,且大大增强了主轴在高点位置的刚性。

4.机床工作台采用双层加强型设计,工作台厚度的增加,有效的隐藏了直线导轨滑座的安装对工作台的干涉,进一步增强了刚性。

5.机床X\Y\Z轴导轨都采用大跨度比的方式,在整体上增加了机床的重量,进而提高了机床的稳定性。

6.机床滚珠丝杠螺母为加长型设计,丝母的预紧力得到了有效的提高,大大延长机床的使用寿命与精度的保持性。

7.机床滚珠丝杠采用预配锁紧螺母结构,有效防止锁紧螺母松动。

8.机床采用我们独创的主动式润滑系统,由数控系统

直接控制油泵出油,真正做到了按需注油,并且可以感知机床油路所产生的问题及时为客户产生预警防止机床损坏。

9.机床采用支撑式滑轮组内防护设计,使内防护在运动时,始终与导轨保持平行,不易产生变形,提高了防水性,延长了使用寿命。

10.每台机床都要根据客户的用途,进行精确配比Z轴配重的重量。根据客户所生产的产品针对性优化机床。

1. The machine body adopts the original three-dimensional diameter reducer design through finite element analysis, and the structure is optimized to the maximum extent. Make the body not only stable and reliable, but also preventthe body deformation and improve the service life.

2.The original three-dimensional diameter reducer design can effectively solve the internal stress of dispersed body. Prevent body deformation.

3.The design of composite worktable can reduce the influence of the fixed bolts of the line rail slide seat on the accuracy of the worktable. And maximize the rigidity of the workbench.

4.X axis adopts two roller heavy load strong rail and six slide seat design, greatly increasing the contact area between slide seat and line rail. Maximizes rigidity during strong and high speed cutting and reduces cutting vibration.

5.Y axis adopts four roller heavy load strong rail and eight sliding seat design. The contact surface of the body of the four line rails and the contact surface of the screw bearing seat are positioned and shaped by the precision machining of the high-precision CNC guideway grinder, and the installation is constantly calibrated by the laser autoquasi instrument. It solves and overcomes the problems of low precision and high failure r when multiple rail is installed.

6.The column of Z axis adopts the "pagoda type stacking" structure, which can absorb the impact of heavy cutting and high-speed cutting in the processing link. Provides high rigidity against vibration.Especially highlight the advantages of rigid tapping and boring.

7. Preconfigured lock nut design. The locking nuts at both ends of the ball screw are prearranged to ensure that the locking nuts are in contact with the end face. Reduce the variation of precision caused by thermal expansion of lead screw.

8. Using our original active lubrication system, the CNC system directly controls the oil output from the oil pump, whichtruly realizes the oil injection on demand, and can sense the problems caused by the oil circuit of the machine tool, generate early warning in time, prevent the damage of the machin tool and improve the service life of the machine tool.

项目名称 | XYZ坐标行程 XYZ axis travel | 主轴中心到Z向导轨面距离 Spindle center to Column surface | 主轴端面到工作台距离Spindle nose to table surface | Z轴切削速度 Z axis feed speed |

值 | 500 400 400 | 475 | 120-520 | 1-10000 |

单位/Unit | mm | mm | mm | mm/min |

项目名称 | 工作台规格(长x宽) Table size | 最大载重 Max. table load | T型槽(槽数X槽宽X槽距) T slot qty-width*distance | 快速位移 Rapid feed speed |

值 | 600*400 | 300 | 3*14*155 | 24/36 |

单位/Unit | mm | kg | mm | mm/min |

项目名称 | 主轴转速范围 Spindle speed | 主轴锥孔 Spindle taper | 刀具数量 Standard tool number | 主轴伺服电机 Spindle servo motor power |

值 | 50-20000 | BT30-100 | 16pcs(options) | 5.5 |

单位/Unit | r/min | type | KW | |

项目名称 | X、Y、Z轴伺服电机 XYZ axis servo motor power | 数控系统 Control system | 定位精度 Positioning accuracy | 重复定位精度Repeated accuracy |

值 | βis8/βis12 | FANUC/SIEMENS/MITSUBISHI/SYNTEC/KND | 300/±0.005 | 300/±0.003 |

单位/Unit | KW | mm | mm | |

项目名称 | 气源压力 Air source pressure | 电器容量 Electrical capacity | 机床轮廓寸(LxWxH) Overall dimension (L x W x H) | 机床重量(约)Weight(about) |

值 | 0.6 | 16 | 2600*2040*2210 | 4.8 |

单位/Unit | MPa | KW | mm | T |

项目名称 | XYZ坐标行程 XYZ axis travel | 主轴中心到Z向导轨面距离 Spindle center to Column surface | 主轴端面到工作台距离Spindle nose to table surface | Z轴切削速度 Z axis feed speed |

值 | 650 450 450 | 525 | 120-570 | 1-10000 |

单位/Unit | mm | mm | mm | mm/min |

项目名称 | 工作台规格(长x宽) Table size | 最大载重 Max. table load | T型槽(槽数X槽宽X槽距) T slot qty-width*distance | 快速位移 Rapid feed speed |

值 | 900*460 | 500 | 5*18*90 | 24/36 |

单位/Unit | mm | kg | mm | mm/min |

项目名称 | 主轴转速范围 Spindle speed | 主轴锥孔 Spindle taper | 刀具数量 Standard tool number | 主轴伺服电机 Spindle servo motor power |

值 | 50-8000 | BT40-150 | 24pcs(options) | 7.5 |

单位/Unit | r/min | type | KW | |

项目名称 | X、Y、Z轴伺服电机 XYZ axis servo motor power | 数控系统 Control system | 定位精度 Positioning accuracy | 重复定位精度Repeated accuracy |

值 | βis12/βis12/βis22 | FANUC/SIEMENS/MITSUBISHI/SYNTEC/KND | 300/±0.005 | 300/±0.003 |

单位/Unit | KW | mm | mm | |

项目名称 | 气源压力 Air source pressure | 电器容量 Electrical capacity | 机床轮廓寸(LxWxH) Overall dimension (L x W x H) | 机床重量(约)Weight(about) |

值 | 0.6 | 19-25 | 2670*2078*1950 | 5.5 |

单位/Unit | MPa | KW | mm | T |

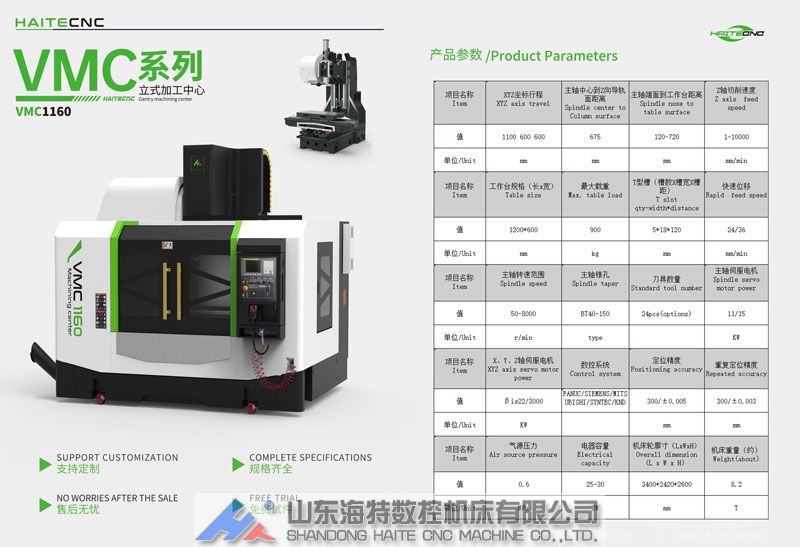

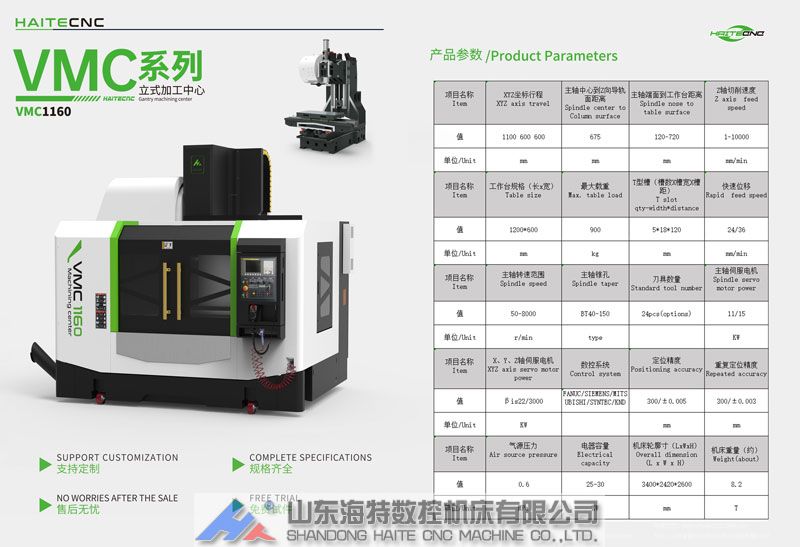

项目名称 | XYZ坐标行程 XYZ axis travel | 主轴中心到Z向导轨面距离 Spindle center to Column surface | 主轴端面到工作台距离Spindle nose to table surface | Z轴切削速度 Z axis feed speed |

值 | 1100 600 600 | 675 | 120-720 | 1-10000 |

单位/Unit | mm | mm | mm | mm/min |

项目名称 | 工作台规格(长x宽) Table size | 最大载重 Max. table load | T型槽(槽数X槽宽X槽距) T slot qty-width*distance | 快速位移 Rapid feed speed |

值 | 1200*600 | 900 | 5*18*120 | 24 |

单位/Unit | mm | kg | mm | mm/min |

项目名称 | 主轴转速范围 Spindle speed | 主轴锥孔 Spindle taper | 刀具数量 Standard tool number | 主轴伺服电机 Spindle servo motor power |

值 | 50-8000 | BT40-150 | 24pcs(options) | 11/15 |

单位/Unit | r/min | type | KW | |

项目名称 | X、Y、Z轴伺服电机 XYZ axis servo motor power | 数控系统 Control system | 定位精度 Positioning accuracy | 重复定位精度Repeated accuracy |

值 | βis22/3000 | FANUC/SIEMENS/MITSUBISHI/SYNTEC/KND | 300/±0.005 | 300/±0.003 |

单位/Unit | KW | mm | mm | |

项目名称 | 气源压力 Air source pressure | 电器容量 Electrical capacity | 机床轮廓寸(LxWxH) Overall dimension (L x W x H) | 机床重量(约)Weight(about) |

值 | 0.6 | 25-30 | 3400*2420*2600 | 8 |

单位/Unit | MPa | KW | mm | T |

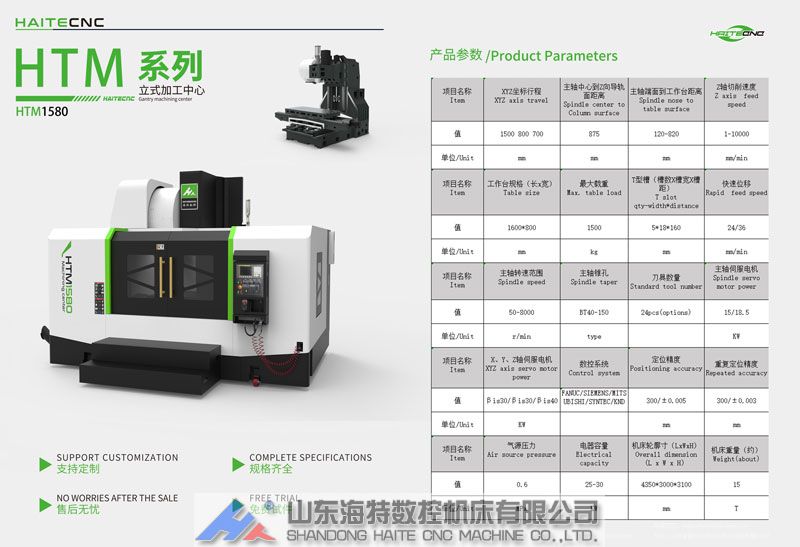

项目名称 | XYZ坐标行程 XYZ axis travel | 主轴中心到Z向导轨面距离 Spindle center to Column surface | 主轴端面到工作台距离Spindle nose to table surface | Z轴切削速度 Z axis feed speed |

值 | 1200 600 650 | 675 | 120-770 | 1-10000 |

单位/Unit | mm | mm | mm | mm/min |

项目名称 | 工作台规格(长x宽) Table size | 最大载重 Max. table load | T型槽(槽数X槽宽X槽距) T slot qty-width*distance | 快速位移 Rapid feed speed |

值 | 1300*600 | 900 | 5*18*120 | 24 |

单位/Unit | mm | kg | mm | mm/min |

项目名称 | 主轴转速范围 Spindle speed | 主轴锥孔 Spindle taper | 刀具数量 Standard tool number | 主轴伺服电机 Spindle servo motor power |

值 | 50-8000 | BT40-150 | 24pcs(options) | 11/15 |

单位/Unit | r/min | type | KW | |

项目名称 | X、Y、Z轴伺服电机 XYZ axis servo motor power | 数控系统 Control system | 定位精度 Positioning accuracy | 重复定位精度Repeated accuracy |

值 | βis22/3000 | FANUC/SIEMENS/MITSUBISHI/SYNTEC/KND | 300/±0.005 | 300/±0.003 |

单位/Unit | KW | mm | mm | |

项目名称 | 气源压力 Air source pressure | 电器容量 Electrical capacity | 机床轮廓寸(LxWxH) Overall dimension (L x W x H) | 机床重量(约)Weight(about) |

值 | 0.6 | 25-30 | 3400*2420*2600 | 8.8 |

单位/Unit | MPa | KW | mm | T |